prolist

contact

- Call:86-15903649888

- Tel:86-371-67856611

- MSN:li@xkps.com

- http://www.51psj.org.cn

- EMAIL:li@xkps.com

- Zip:450001

- Address: No.2, Lvhuan Road,

- Huiji Dist, Zhengzhou, Henan,

- China (Mainland)

Cone crusher

Description of Cone Crusher

Cone crusher is suitable to crush various kinds of ores and rocks of medium or above medium hardness. Compare with jaw crusher, cone crusher is of stable structure, high efficiency, easy adjustment, and use economically, etc. The spring safety system of crusher acts as an overloading protection system that allows metals to pass through the crushing chamber so as not to damage the cone crusher. The safety system uses dry oil and water as two kinds of sealed formation to make plaster powder and engine oil separated to make sure reliable performance. The type of crushing chamber depends upon the size of feeding and fineness of the crushed product. The standard type(PYB) is applied to medium crushing, the medium type is applied to medium or fine crushing and the short head type is applied to fine crushing.

Application of Cone Crusher

Cone crusher is suitable to crush various kinds of ores and rocks of medium or above medium hardness. Compare with jaw crusher, cone crusher is of stable structure, high efficiency, easy adjustment, and use economically, etc. The spring safety system of crusher acts as an overloading protection system that allows metals to pass through the crushing chamber so as not to damage the cone crusher. The safety system uses dry oil and water as two kinds of sealed formation to make plaster powder and engine oil separated to make sure reliable performance. The type of crushing chamber depends upon the size of feeding and fineness of the crushed product. The standard type(PYB) is applied to medium crushing, the medium type is applied to medium or fine crushing and the short head type is applied to fine crushing.

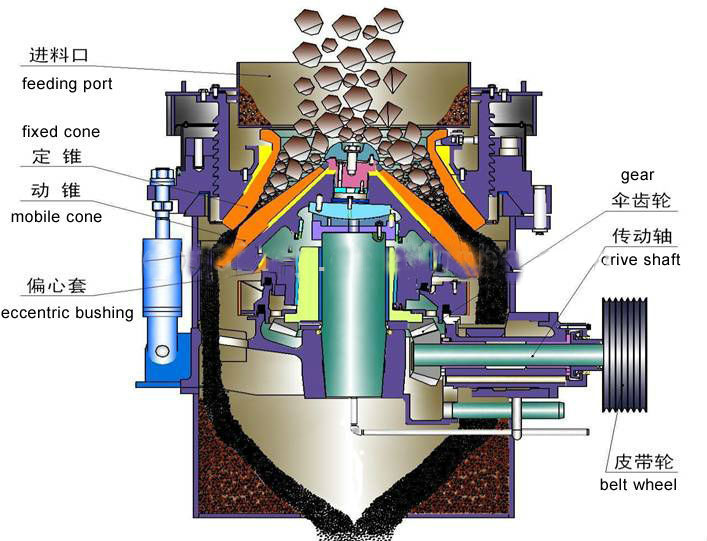

Working Principle of Cone Crusher

Cone crusher crushes materials by the working surface between the movable cone and fixed cone. So it is more advanced and efficiency efficient than jaw crusher. The movable cone is supported by spherical bearing and fixed on an hanging erect shaft which is set in the eccentric sleeve, and the sleeve is set on the stopping and pushing bearing. The movable cone and erect shaft are driven by the eccentric shaft sleeve together. The eccentric shaft sleeve is driven by horizontal shaft and fimbriated gear, and the wheel of the conveyor belt is driven by motor through v-belts. The lower part of vertical shaft is installed in the eccentric sleeve. When the eccentric sleeve rotates, there is a conical surface lined out by the shaft. When the movable cone comes near the fixed cone, rocks are grinded into pieces, when the movable cone leaves, grinded materials is discharged from the discharge hole. The fixed cone can be ascended or descended by adjusting setting to adjust the width of discharge hole, consequently the output size is determined adjusted.

Advantages of Spring Cone Crusher

1. High reliability, good stability

It adopts big diameter shaft, high-duty main frame, independent thin oil lubrication system and indpendent automatic control system, thus make sure the equipment is durable and reliable. It can rapidly recover the discharge port and gurantee the discharge size by the hard protection device.

2. Convenient maintenance, easy operation

There is no filling in the joints of wearing parts and equipment body. They are mechanical fastening. So it is easy for replacement and save much time and effort.

3. Low operating cost, wide field of application

This machine can reduce the production cost heavily. It adopts the laminated crushing principle, forming the material protective layer. It can not only reduce the abrasion and extend the wearing parts using life, but can also increase the proportion of the cubic products and make them more uniform.

4. Good protection performance. with the hydraulic cavity cleaning function

Cone crusher must be full load feeder in order to achieve the effect of lamination if we want to get the max output. But this way may cause the problem of material block. You need to open the upper cover and clean the cavity by hand if you use the traditional cone crushers.

Main technical parameter

|

Model |

Cone dia

mm |

Feed size

mm |

Outsize adjustable range

mm |

Capacity

t/h |

Power

kw |

Rotate speed

r/min |

Weight

t | |

|

PYB |

900 |

900 |

115 |

15-50 |

50-90 |

|

|

11.2 |

|

PYZ |

60 |

5-20 |

20-65 |

55 |

333 |

11.2 | ||

|

PYD |

50 |

3-13 |

15-50 |

|

|

11.3 | ||

|

PYB |

1200 |

1200 |

145 |

20-50 |

110-168 |

|

|

24.7 |

|

PYZ |

100 |

8-25 |

42-135 |

110 |

300 |

25 | ||

|

PYD |

50 |

3-15 |

18-105 |

|

|

25.3 | ||

|

PYB |

1750 |

1750 |

215 |

25-50 |

280-480 |

|

|

50.3 |

|

PYZ |

185 |

10-30 |

115-320 |

160 |

245 |

50.3 | ||

|

PYD |

85 |

5-13 |

75-230 |

|

|

50.2 | ||

|

PYB |

2200 |

2200 |

300 |

30-60 |

59-1000 |

|

|

80 |

|

PYZ |

230 |

10-30 |

200-580 |

260-280 |

220 |

80 | ||

|

PYD |

100 |

5-15 |

120-340 |

|

|

81. | ||

Company Information

Established in 1980, Henan Zhongke Engineering & Technology Co., Ltd, is a large modern high-tech enterprise in China construction & mining machinery fields, with RMB1.93 Billion of total asset, RMB 0.34 billion of fixed asset, and 1500 employees. The main products are construction equipments,mining equipments,sand & stone making equipments and cement quipments.