prolist

contact

- Call:86-15903649888

- Tel:86-371-67856611

- MSN:li@xkps.com

- http://www.51psj.org.cn

- EMAIL:li@xkps.com

- Zip:450001

- Address: No.2, Lvhuan Road,

- Huiji Dist, Zhengzhou, Henan,

- China (Mainland)

Autoclave Boiler

Autoclave Boiler

Aerated concrete block production at the environment of high temperature and saturated steam, so the aerated concrete block production line according to the general requirements when the boiler equipment production allocation rated working pressure of 1.6 Mpa, the steam boiler temperature above 200 ℃.

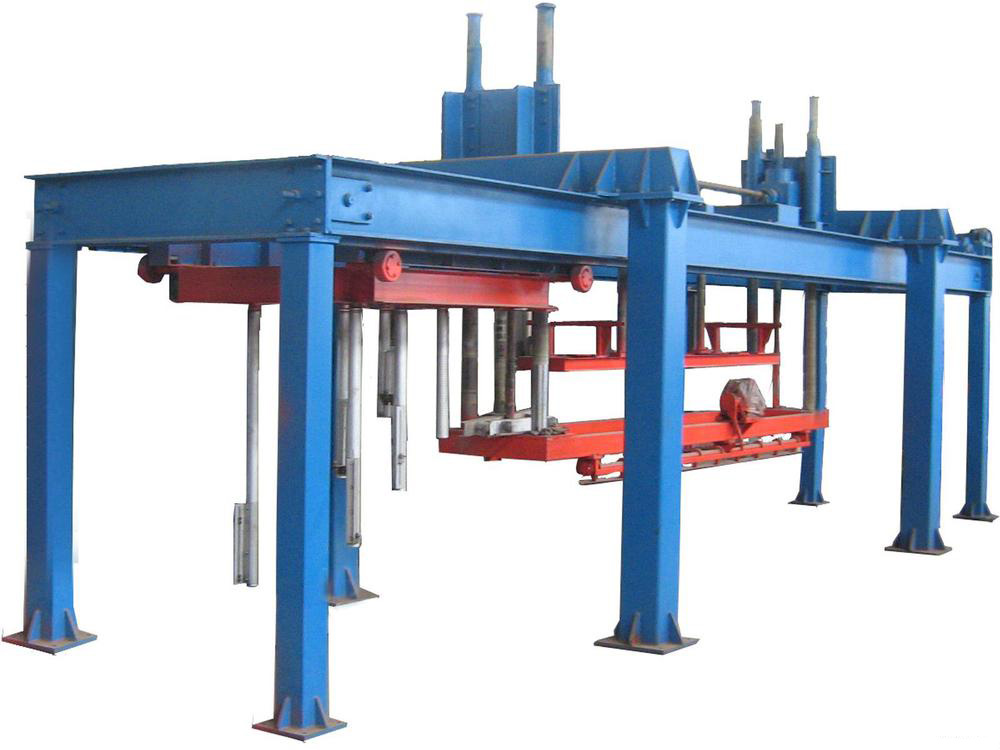

mould

mould

Mould is AAC production major ancillary equipment.After the raw materials uniform mixing, it is pouring into the mould,solidifying and expanding After curing, off-mould, which can be cut.

Pouring mixer

Pouring mixer

Aerated concrete Pouring mixer is the main equipment in the production of aerated concrete, and is mainly applicable for mixing the slurry, cement, quicklime, gypsum, and liquid of aluminium paste which are poured into tank in accordance with certain proportion, to make them well-proportioned and reacted with each other adequately. Then it pours the mixed slurry into mould frame in due course.

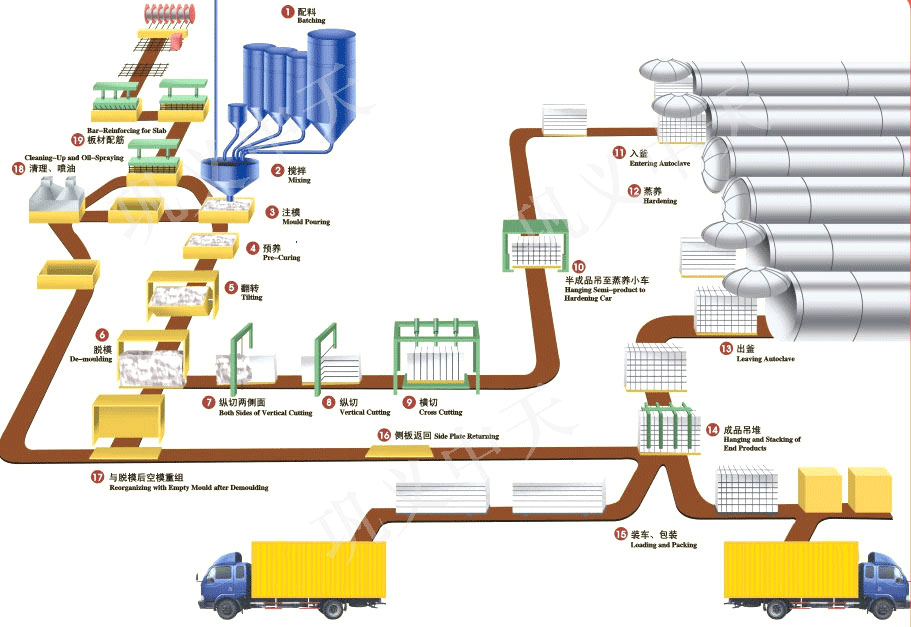

Autoclaved Aerated Concrete (AAC) Equipments

Autoclaved Aerated Concrete (AAC) Equipments

Autoclaved Aerated Concrete (AAC) block and board have become the pillar industry in construction field. China (Mainland) has introduced AAC technology before 40 years, our company is the earliest manufacture and R?D institute of Aerated Concrete (AAC) machinery, and our technology has reached the advanced level of Aerated Concrete (AAC) machine industry.

Cutting Machine

Cutting Machine

Cutting machine is the main equipment for Autoclave Aerated Concrete(AAC) products, it�s necessary core equipments for capacity more than 50000m³/year, it�s also necessary to increase the AAC capacity. Our JQF series cutting machine adopts advanced technology