prolist

contact

- Call:86-15903649888

- Tel:86-371-67856611

- MSN:li@xkps.com

- http://www.51psj.org.cn

- EMAIL:li@xkps.com

- Zip:450001

- Address: No.2, Lvhuan Road,

- Huiji Dist, Zhengzhou, Henan,

- China (Mainland)

Jaw Crusher

Description of Jaw Crusher

Jaw crusher is ideal for the primary and secondary crushing, is widely used in mining, quarry, metallurgy, building, highway, railway, construction waste processing, water conservancy and chemical industry, etc. It features in high reduction ratio, easy operation, simple construction, repeatable performance, easy maintenance, and low consumption.

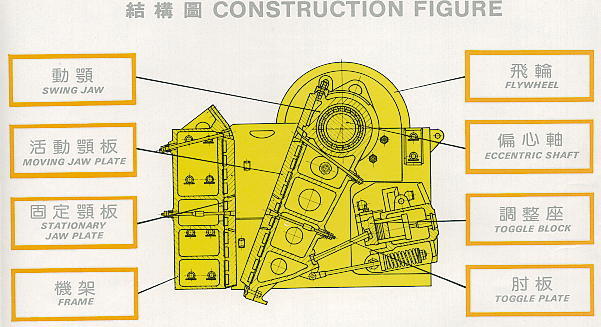

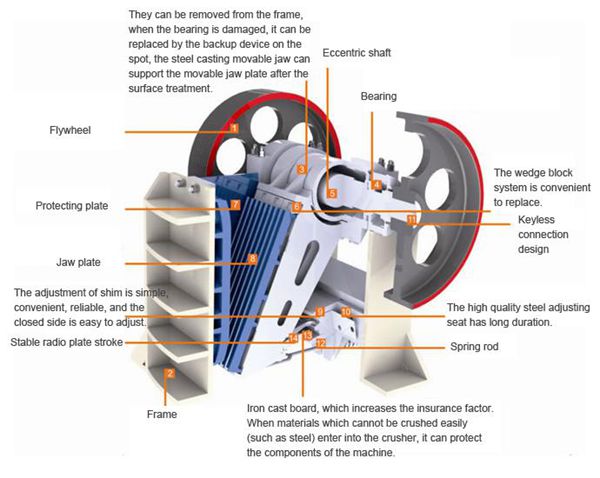

Construction figure of Jaw Crusher

Jaw crushers are heavy duty machines and hence need to be robustly constructed. The outer frame is generally made of cast iron or steel. The jaws themselves are usually constructed from cast steel. They are fitted with replaceable liners which are made of manganese steel, or Ni-hard (a Ni-Cr alloyed cast iron).Jaw crushers are usually constructed in sections to ease the process transportation if they are to be taken underground for carrying out the operations.

Working principle of Jaw Crusher

Jaw crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism. The jaws are farther apart at the top than at the bottom, forming a tapered chute so that the material is crushed progressively smaller and smaller as it travels downward until it is small enough to escape from the bottom opening. The movement of the jaw can be quite small, since complete crushing is not performed in one stroke. The inertia required to crush the material is provided by a weighted flywheel that moves a shaft creating an eccentric motion that causes the closing of the gap.

Features of Jaw Crusher

Deep crushing cavity and no dead time control have improved the feeding capability and the production output. Large crushing ratio and even particle size. .Gasket discharge opening adjustment equipment makes the function more reliable and convenient , adjustment more large ,and the equipment more flexible .The lubrication system more secure and reliable ,the spare parts can be more changed ,and low maintenance working..Simple structure and relable function,low operation cost.Energy-saving : the single machine can make the energy-saving about 15%~30% and the system energy-saving over one time. .Large range of the discharge opening range can satisfy the various requirements of the customers . Low noise and dust pollution.

]

Technical parameters

|

Model |

Max feed size

mm |

Adjust size

mm |

Capacity

m³/h |

Rotate speed

r/min |

Power

kw |

Weight

kg |

|

PEF150X250 |

125 |

10-40 |

1-3 |

285 |

7.5 |

700 |

|

PEF200X300 |

165 |

20-70 |

2-8 |

265 |

11 |

800 |

|

PEF250X400 |

210 |

20-80 |

5-20 |

310 |

18.5 |

3000 |

|

PEF400X600 |

340 |

40-90 |

10-40 |

275 |

30 |

7200 |

|

PEF350X750 |

290 |

30-55 |

20-50 |

300 |

37 |

8900 |

|

PEF500X750 |

425 |

50-100 |

34-68 |

275 |

55 |

11320 |

|

PEF600X900 |

480 |

75-200 |

40-120 |

255 |

75 |

17600 |

|

PEF750X1060 |

630 |

80-200 |

80-160 |

250 |

90 |

30530 |

|

PEF900X1200 |

750 |

100-200 |

110-200 |

250 |

110 |

50000 |

|

PEF1000X1200 |

850 |

195-265 |

315-500 |

200 |

110 |

55000 |

|

PEF1200X1500 |

1020 |

150-300 |

400-800 |

180 |

160 |

100000 |

|

PEX150X750 |

125 |

10-40 |

5-15 |

300 |

15 |

3600 |

|

PEX250X750 |

210 |

15-55 |

10-32 |

300 |

30 |

7350 |

|

PEX250X1200 |

210 |

15-60 |

12-38 |

300 |

37 |

8700 |

|

PEX300X1300 |

250 |

20-90 |

16-65 |

300 |

55 |

11600 |

Company Information

Established in 1980, Henan Zhongke Engineering & Technology Co., Ltd, is a large modern high-tech enterprise in China construction & mining machinery fields, with RMB1.93 Billion of total asset, RMB 0.34 billion of fixed asset, and 1500 employees. The main products are construction equipments,mining equipments,sand & stone making equipments and cement quipments.