prolist

contact

- Call:86-15903649888

- Tel:86-371-67856611

- MSN:li@xkps.com

- http://www.51psj.org.cn

- EMAIL:li@xkps.com

- Zip:450001

- Address: No.2, Lvhuan Road,

- Huiji Dist, Zhengzhou, Henan,

- China (Mainland)

Cement Mill

Description of Cement Mill

Ball cement mill is widely used in many industries ,such as ferrous metal ,nonferrous metal ,nonmetal mines ,construction ,electricity ,coal ,traffic ,light industry and so on .The energy saving ball mill produced by our company adopt rolling bearing support instead of gleitlargebuchsen suppot .Comparing with gleitlargebuchsen ,the rolling bearing can save 10-20% energy ,the capacity will enlarge 10-20% .

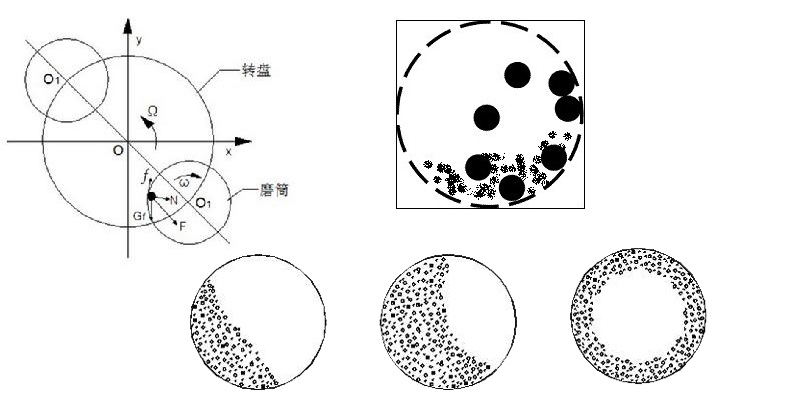

Working principle of low cost rolling bearing ball cement mill

The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Features of Cement Mill

1,The ball cement mill is made up of feeding part, discharging part, gyre part, transmission part, (decelerator, small transmission gear, generator, electrical control) and so on. 2,The hollow axis adopts the cast steel and the lining can replace, the rotating big gear processes in the way of casting rolling gear. 3,The cylinder is wearable well and bears wearable lining board.

Cement Mill

|

Spec /m |

Φ2.2 ×6.5 |

Φ2.2 ×11 |

Φ2.2 ×13 |

Φ2.4 ×8 |

Φ2.4 ×13 |

Φ2.6 ×13 |

Φ3 ×9 |

Φ3 ×11 | |

|

Capacity t/h |

13—14 |

15 —16 |

16 —18 |

15 |

20 —23 |

30 —32 |

28 —32 |

36 —40 | |

|

Rotary speed r/min |

22 |

21 |

21.5 |

20.8 |

19 |

19.6 |

17.8 |

18 | |

|

Feed size mm |

<25 |

<25 |

<25 |

<25 |

<25 |

<25 |

<25 |

<25 | |

|

Grinding media weight /t |

31 |

50 |

60 |

45 |

65 |

80 |

70 —80 |

100 | |

|

Cubage m3 |

21.4 |

36 |

43 |

|

51.7 |

60 |

55 |

69 | |

|

Drive |

Edge |

Center |

Center |

Edge |

Center |

Edge |

Center |

Center | |

|

Motor |

Power /kw |

380 |

630 |

630 |

560 |

800 |

1000 |

1000 |

1250 |

|

Volte /v |

6000 |

6000 |

6000 |

6000 |

6000 |

10000 |

6000 |

6000 | |

|

Reducer |

Z D70 |

D110 |

D110 |

ZDY 560A |

D110 |

JD—800 |

D125 |

D140S | |

|

Dime-nsion |

L /mm |

12385 |

21559 |

26079 |

17215 |

27580 |

20883 |

23568 |

27610 |

|

W /m |

5390 |

4540 |

4540 |

5564 |

4540 |

7740 |

4760 |

5720 | |

|

H /mm |

4210 |

3520 |

3520 |

4540 |

3620 |

5670 |

3670 |

4080 | |

|

Weight /t |

53 |

109 |

114.2 |

82.53 |

138 |

144.5 |

138.7 |

181.9 | |

|

Spec /m |

Φ3 ×11 |

Φ3.2 ×11 |

Φ3.5 ×9.5 |

Φ3.5 ×11 |

Φ3.6 ×8.5 |

Φ3.8 ×9 |

Φ3.8 ×12.5 |

Φ3.8 ×13 | |

|

Capacity t/h |

36 |

40—45 |

40 |

45 |

60 |

70 —80 |

55 |

60 | |

|

Rotary speed r/min |

17.69 |

17.4 |

18 |

17.2 |

16.5 |

16.5 |

16.4 |

16.3 | |

|

Feed size mm |

<25 |

<15 |

<20 |

<15 |

<20 |

<20 |

<25 |

<25 | |

|

Grinding media weight /t |

100 |

90~100 |

115 |

116 |

102 |

130 |

167 |

173 | |

|

Cubage m3 |

69 |

69 |

76.4 |

78.5 |

|

94 |

|

| |

|

Drive |

Edge |

Center |

Center |

Center |

Center |

Center |

Edge |

Center | |

|

Motor |

Power /kw |

1250 |

1250 |

1400 |

1600 |

2500 |

2000 |

2500 |

2500 |

|

Volte /v |

6000 |

6000 |

6000 |

6000 |

6000 |

6000 |

6000 |

6000 | |

|

Reducer |

ZDY140S |

D40 |

ZJA 2060A |

ZJ 2240 |

|

ZJ2240A |

MB25-II |

| |

|

Dime- nsion |

L /mm |

24567 |

28000 |

29717 |

28454 |

19693| (no drive) |

28521 |

17419 |

19693 (no drive) |

|

W /m |

7510 |

5720 |

5250 |

5350 |

4141 (no drive) |

5550 |

10745 |

4141 (no drive) | |

|

H /mm |

5968 |

3672 |

5000 |

5600 |

5404.5 |

5600 |

8204 |

5404.5 | |

|

Weight /t |

156.5 |

180 |

194.4 |

271.64 |

223.3 (no drive) |

255.2 |

301.4 |

223.3 (no drive) | |

Company Information

Established in 1980, Henan Zhongke Engineering & Technology Co., Ltd, is a large modern high-tech enterprise in China construction & mining machinery fields, with RMB1.93 Billion of total asset, RMB 0.34 billion of fixed asset, and 1500 employees. The main products are construction equipments,mining equipments,sand & stone making equipments and cement quipments.